Agricultural processing facilities in 2025 operate under strict quality and hygiene expectations. From seed intake to storage and distribution, every stage requires clean handling equipment to prevent contamination. One of the most critical yet often overlooked machines supporting this process is the seed box washer. Designed to clean reusable containers efficiently, this system ensures that seeds are handled in a controlled and sanitary environment.

Why Clean Seed Containers Matter

Seed boxes are repeatedly used throughout harvesting, sorting, and storage processes. Over time, residues such as soil particles, plant matter, moisture, and microorganisms accumulate on container surfaces. If left uncleaned, these residues can compromise seed quality and introduce unwanted pathogens. A seed box washer eliminates these risks by delivering consistent and thorough cleaning after each use.

Evolution of Washing Technology in Agriculture

Earlier cleaning methods relied heavily on manual labor and basic rinsing techniques. These methods lacked consistency and consumed excessive water. Modern washing systems now use precision-engineered spray patterns, temperature control, and automated cycles. This evolution allows agricultural facilities to maintain high sanitation levels while improving speed and efficiency across operations.

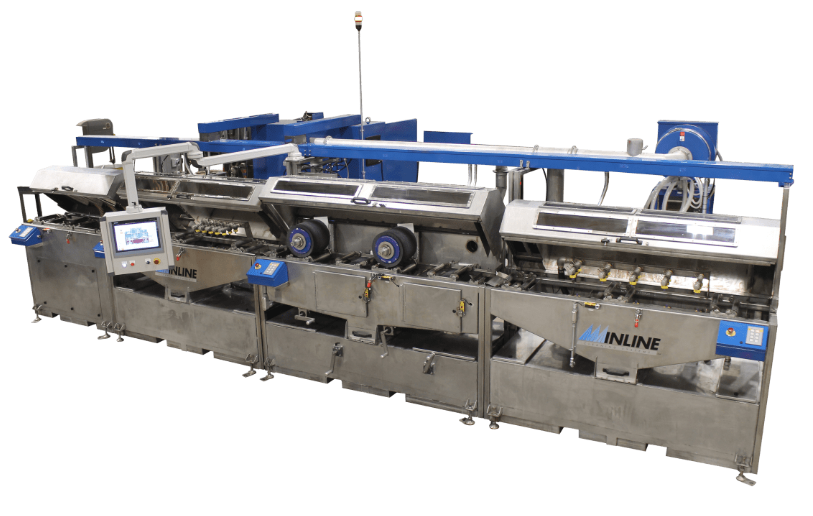

Design and Performance Capabilities

Contemporary washing systems are built to handle continuous workloads without sacrificing performance. High-capacity pumps generate controlled water pressure that removes stubborn debris without damaging container surfaces. Adjustable wash parameters allow operators to tailor cycles according to contamination levels and container materials, ensuring optimal results every time.

Contribution to Operational Consistency

Consistency is essential in large-scale agricultural processing. Automated washing equipment ensures that every container is cleaned to the same standard regardless of volume or shift changes. This reliability supports smoother downstream processes such as filling, sealing, and labeling, reducing disruptions caused by contamination or equipment issues.

Supporting Regulatory and Quality Standards

Regulatory bodies increasingly focus on sanitation and traceability within agricultural supply chains. Using a seed box washer helps facilities demonstrate compliance with cleanliness requirements and internal quality protocols. Clean containers reduce the likelihood of inspection failures and protect the reputation of agricultural brands operating in competitive markets.

Resource Optimization and Cost Control

Efficient use of water and energy is a priority for agricultural businesses. Modern washing systems incorporate water recovery and filtration technologies that significantly reduce waste. By reusing treated water and optimizing heating cycles, facilities lower operational costs while maintaining strong hygiene performance.

Integration into Existing Facility Layouts

Seed box washers are designed to integrate seamlessly into both new and existing facilities. Modular construction allows customization based on available space and production volume. Whether installed as a standalone unit or part of an automated line, these systems enhance workflow efficiency without major structural changes.

Conclusion

The seed box washer plays a vital role in maintaining sanitation, efficiency, and compliance within modern agricultural operations. By delivering consistent cleaning performance, reducing resource consumption, and supporting seed quality, this equipment has become an essential investment. As agricultural facilities continue to modernize, reliable container washing solutions remain a cornerstone of sustainable and productive seed handling systems.

Write a comment ...